A shift in mindset

Recognizing the vast gap between societal needs and sustainable building solutions, Adapteo remains steadfast in leading the market in circular social infrastructure, while respecting planetary boundaries.

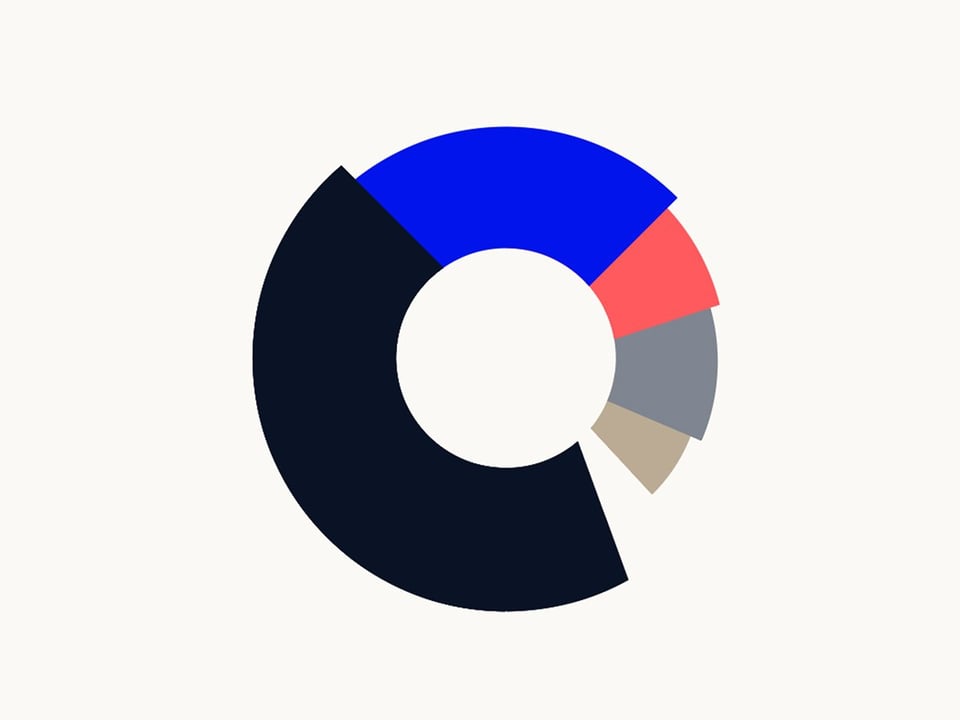

Our corporate strategy rests on three strategic pillars, weaving sustainability into every aspect of our business. We champion a 'theory of change', placing adaptivity at the forefront – a resilience born from agility and flexibility in the face of change. This ethos, inherent in our products, is in all facets of our operations.